LEGAL NOTICES: ATTENTION- 2024 Update: “You could become a Felon without even knowing it; effecting your right to even own a gun!”

Residents of CA, CT, DE, DC, IL, KS, MA, NY, WA, parts od OH, MD. This ALSO includes any other state not listed here. Especially in major population areas, even in states, that never had any type of law or a city (local legal/regulatory requirement) in effect. You must keep informed! Due to the political atmosphere in populated areas of our country; Anti-gun and/or Ammunition laws can be added or changed, at any time, without any official (Legal or Not) public notification “If you have NOT ordered ammo over the internet BEFORE or NOT RECENTLY”. You must check your state and local city regulation laws; covering ammo purchases, before ordering ammunition products over the internet. By placing an order on this web site or directly by phone; you Certify, that you are of legal age (18 years or older) and satisfy all federal, state and local legal/regulatory requirements. Prior to purchase of ammunition, from TarHunt Custom Rifles Inc and then have that ammo shipped to your legal residents.

Especially residents of CA, NY, CT, RI, MA, DE, DC, IL, KS, WA, OH, MD and any state you are NOT SURE ABOUT. This list was current. As fast as the ammo laws are changing; only use it as a guide as to WHERE the hot areas were, when this list was compiled. ONLY GOD KNOWS BY NOW! If you do live in a known restricted area, your order may be cancelled.

California – No Sales to the cities of Los Angeles, Oakland, Sacramento, San Francisco, or Avalon. All ammo must be shipped thru an FFL holder, with a waiting period and service charges apply.

Delaware- Has a few restricted counties. Check your local laws.

Connecticut & Rhode Island- Only with a copy of your concealed hand gun permit on file.

Hawaii – No Sales Period. Use an importer, buy another tytle.

Massachusetts – Only with a copy of your concealed hand gun permit on file.

Maryland – No Sales to the City of Annapolis and Montgomery County.

New Jersey – Must have a current Firearms ID card on file.

New York – No Sales to New York City, or its five Burroughs of NYC. All ammo shipped to NY state, must be shipped thru an FFL holder, with a waiting period and service charges apply.

No sales Washington DC.

No sales in Illinois into the city of Chicago or Cook County. Illinois: All other Illinois residents must supply us a copy of your FOID card. We must ship to the address on the FOID card.

Premier: 20ga 2.2” Schrifle™ 365gr Copper slug Round. (Schri`ful). “No longer just a slug gun; but not quite a rifle, NOW, its a Schrifle”!

The Schrifle 2.2″ Round is NOT for use in a rifled barrel with a 3″ chamber, any smooth bore barrel, any type of a fixed choke, choke tube, RIFLED choke tube, or a Hastings rifled barrel!

The 2.2” Schrifle™ 365gr Slug round must ONLY be used in its own 2.2” length chamber. It is too sensitive to outdoor hunting season temperatures, when fired in a 3” factory chamber. In cold temperatures (below 30 degrees) the Schrifle™ round can experience lower internal PRESSURE variations and possible slug misalignment to the bore; causing poor accuracy! HOWEVER; the Schrifle™ slug is now available, as the 20ga 3” NeoTec™ FLC [Full Length Chamber] round. A 355gr bore size Copper Slug at 1785ft/sec, but loaded in a factory hull/case. This round was specifically designed for fully rifled barrels with a 3” factory chamber. Check out the web site for more info, [ tarhunt.com ]. On the home page menu bar, at the top right side, under the word AMMO; 4th line down, 20ga 3” NeoTec FLC info.

Limited rounds, now available off of the [ tarhunt.com ] web site. Home page, on the menu bar, under the word “AMMO. “The Terms and Conditions are subject to change at TarHunt Inc. sole discretion without prior notice. Any changes made are effective upon posting.

TarHunt is not responsible for any and all damages to the firearm(s), person(s) firing the firearm, and/or person(s) as bystanders, due to the improper installation of a TarHunt barrel by anyone other than a TarHunt employee. The failure of a Savage 220 action, or the use of the TarHunt Schrifle series of bore size Copper slugs, the NeoTec FLC series of bore size Copper slugs in a Hastings or any other rifled barrel that does not comply with SAAMI rifled barrel specifications.

Hasting barrel Warning:

Both the 2.2″ Schrifle™ and the NeoTec™ FLC series, all other rounds that may be loaded with the 20ga Copper TarHunt slug(s); are full bore size diameter 20ga Copper slugs. They were manufactured to US- SAAMI SPECIFICATIONS of (.618ths. min & .620ths max. diameter). All 20ga Copper slugs are .619ths IN DIAMETER.

The Hastings rifled barrels were manufactured in France, for Hastings. They were manufactured under C.I.P. European barrel standards. That means they have a smaller .616ths Inside Bore Diameter. The barrels have been known to BLOW OPEN, when a full diameter Copper or Sabot loaed with a solid slug that is a (SAAMI approve round). “These barrels could cause serious personal injuries or death”.

The 2.2″ long Schrifle round is NOT recommended for use in a 2 3/4″ or a 3” chamber! NOTE: If a barrel is chambered for the 2.2″ Schrifle round that is the only round that can be fired in that barrel!

Reference: The right choice slug round for any 20ga rifled barrel with a 3″ chamber is the 20ga 3″ NeoTec™ FLC Copper slug round. Details can be found on its own 20ga 3″ NeoTec FLC information page).

“The only totally NEW slug & case combination in over 100 years.” The 20ga Schrifle round consists of a new “Hollow Bullet with Truss” Copper Slug and a Rifle Style plastic case.  “The only new hollow projectile/with a single truss in over 200 years” The SCHRIFLE (Shri`ful): “No longer just a slug gun, but not quite a rifle, now, it’s a Schrifle.” (Schri`ful)

“The only new hollow projectile/with a single truss in over 200 years” The SCHRIFLE (Shri`ful): “No longer just a slug gun, but not quite a rifle, now, it’s a Schrifle.” (Schri`ful)

The 20ga Schrifle™ slug is the 5th generation of a hunting slug design. It is the ongoing result of over 10 years of research & development. The “out of the box thinking” that culminated into this unique patent design and was only made possible by the advancements in precision machining, new plastic developments, and new molding techniques. Most importantly, the quality control and consistency of the new gun powders over the last decade has vastly improved.

The slug is a 20ga 365gr slug round using a”Hollow Bullet with Truss” Copper slug and a new special 2.2″ length case. The Schrifle round requires its OWN LENGTH CHAMBER for best accuracy and performance! The 365gr Copper slug was the original slug design for the TarHunt 20ga 2.2” Schrifle™ round. It is a PREMIER high performance, full expanding, copper slug. While flying at or near the same velocity as other light weight sabot rounds, it is 26% bigger in diameter and a full 100+grains heavier! This 365gr slug is stable in all known 20ga twist rate barrels. When the 365gr Hollow Copper projectile is loated into the 2.2″ Schrifle case, it has an overall total length of only 2.690″. There is no conversion back to a shorter length chamber without installing a new barrel.

“Bigger is really Better”:

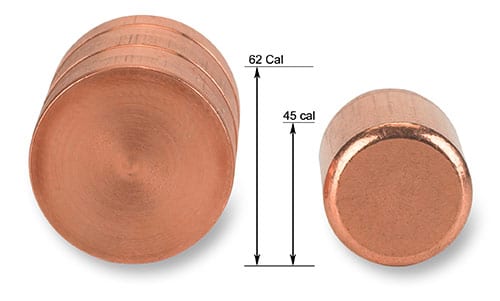

NOW, a slug can be made with the same physical size and shape (as a full bore size slug weighting 1100 grains), but weighting only 365 grains instead. That’s a 2/3 reduction in weight and a 26% increase in diameter over 45cal sabot rounds.  That makes it possible to achieve the same velocities as the much lighter & smaller diameter 45cal sabot rounds, with a full bore size slug.The “20ga Premier Schrifle slug retains aproxamently 83% of the original weight and less than 1% of the flyers are slug related. All other current sabot rounds average 10% to 12% flyers, caused by the inconsistent fit to the bore size of your barrel. That causes less energy and more drop down range than expected! “The 20ga 365gr Copper slug is show here in an actual size comparison to 45cal projectile used in most sabot rounds”. Size ratio remains the same at any magnification.

That makes it possible to achieve the same velocities as the much lighter & smaller diameter 45cal sabot rounds, with a full bore size slug.The “20ga Premier Schrifle slug retains aproxamently 83% of the original weight and less than 1% of the flyers are slug related. All other current sabot rounds average 10% to 12% flyers, caused by the inconsistent fit to the bore size of your barrel. That causes less energy and more drop down range than expected! “The 20ga 365gr Copper slug is show here in an actual size comparison to 45cal projectile used in most sabot rounds”. Size ratio remains the same at any magnification.

THE TECHNOLOGY”: Behind our Hollow Copper Slug.

The “Hollow Slug with Truss” design removes the lead core used in projectiles for over 200 years and replaces it with a strong, light weight, pressurized, elastomer-polymer truss.  This new type of core is flexible enough to allow the side walls of the hollow copper slug to lock into the rifling and upsetting to the inside diameter of the barrel. These two events taking place are critical to insure consistency by eliminating the wild flyers caused by out of round or under-rotated slugs. After the slug has upset in size the pressurized elastomer truss remains strong enough to support the thin wall copper o-jive area (pointed part of the slug) from collapsing inward while the slug is being forced thru the barrel. Upon impact, the pressurized elastomer truss also aids in the rapidly outward expand of the o-jive area.

This new type of core is flexible enough to allow the side walls of the hollow copper slug to lock into the rifling and upsetting to the inside diameter of the barrel. These two events taking place are critical to insure consistency by eliminating the wild flyers caused by out of round or under-rotated slugs. After the slug has upset in size the pressurized elastomer truss remains strong enough to support the thin wall copper o-jive area (pointed part of the slug) from collapsing inward while the slug is being forced thru the barrel. Upon impact, the pressurized elastomer truss also aids in the rapidly outward expand of the o-jive area.

Proper shape and Diameter:

Using this new “Hollow Bullet with Truss” design, a premier bore size 20ga slug can be manufactured while greatly reducing its overall weight. The ideal physical size of a 20ga bore size projectile for the Schrifle round, for use in a 1-24tr barrel, is (1.125ths long x .619ths in diameter). If it were made of solid Copper, It would weigh over 1000gr.

Using this new “Hollow Bullet with Truss” design, a premier bore size 20ga slug can be manufactured while greatly reducing its overall weight. Now a slug can be made with the same physical size and shape, but weighting only 365 grains instead. That’s a 2/3 reduction in weight. Shown here in actual size. Notice that the expanded nose section only fold out at right angles to the body of the slug! They did not fold back along the sides of the slug, making it smaller as it moves forward, after impact! An expanded slug like the one shown, @1800 fps, it’s spinning at 52,000 rpm’s (when fired thru a 1-24 twist rate barrel), and still weighting over 300 grains, after it expands. “It acts just like 1 1/8″ diameter hole saw”!

Why is case length so important for slug accuracy”?

When a shorter case, such as a 2.2″ Schrifle case OR a standard 2 3/4″ slug round, is fired in a longer 3″ factory chamber, you lose a percentage of your chamber pressure every shot. Because the slug must jump thru (almost .700ths of an inch) of unsealed and unguided area between the mouth of the case and the start of the rifling. This random loss of pressure will be even greater in gas operated auto loaders.

The question then becomes with this unguided jump, did the slug enter the rifling straight in line with the bore or off center and become a flyer? The front end of the slug should enter the rifling while the rear of the slug is being held in line with the CENTER OF THE BORE, by a front portion of the case! Both Accuracy and overall Performance will suffer every time a shorter case is fired in a longer 3″ chamber.

The most likely result will be vertical groups. The lower the temperature your hunting in, the greater the pressure loss. The slug could dramatically change its point of impact! “In part because the chamber is not completely sealed when you are using a short case in a 3″chamber”.

When the shorter 2.2″ Schrifle™ case is fired in a 2 ¾” chamber the base of slug has left the mouth of the case by just few thousands before the slug will entering the rifled bore. You will lose very little chamber pressure until the slug enters into the rifling. A few, but not all, 2 ¾” chambers, will shoot reasonable well using the 2.2″ length Schrifle case.

“Shooting a Full bore size Copper slugs in a rifled barrel”

The 365gr Copper slug is a premium bore size slug, and is on track to be largest diameter, heaviest, fastest, full expanding of all the Copper slugs in the industry. While retaining as much as 83% of its original weight when used on thin skin big game. The bore size 3″ 20ga NeoTec FLC 365gr Copper slug has a unique felt recoil. Because of the weight of a bore size Copper slug, locking directly into the rifling. A clock wise twisting effect is applied to the gun as the slug accelerates from ZERO up to 52,000 rpm’s, when it’s fired thru a rifled barrel. The effect may go unnoticed by most shooters but the high left flyer toward 10:30 is often present to some degree. Up and Left, aproxamently 2″ in both directions even at 50yds. Think about what happens when you’re shooting between 100 and 200 yards! That 10:30 flyer was caused by you relaxing/changing the grip on your left hand!

“Gun control required while zeroing off of a shooting bench”

Lead Sleds, usually won’t work to zero a hard kicking rifles; and is even worse trying to zero a slug gun because of the time the slug spends in the barrel, compared to a rifle bullet. If the slug gun is being held to solidly by the lead sled and NOT allowed to slide straight back while the slug is moving thru the barrel; the gun reacts by trying to just jump out of the Lead sled. If there is no real TWO hand gun control the muzzle can be pointed anywhere by the time the slug leaves the muzzle!!

Avoid leaning forward at a sharp angle. Sitting behind a hard recoiling rifle at a sharp angle, the recoil is NOW trying slide you butt or the bench you’re sitting on backwards; causing EVEN more muzzle lift and all that goes with it!

“THIS IS A MUST”– A firm two hand (GRIP) style gun control is required while shooting a slug gun off of a rest. GRIP the slug gun the same way you would hold onto a Big Bore Mag, firing a 350gr bullet at 2500fps! “Not because the recoil is that Sevier”. Because of the amount of TIME it takes the slug to move thru a rifled barrel. While still moving thru the barrel the slug is constantly trying to twist the slug gun clockwise; all the time the slug is in the barrel. If a high left shot consistently frustrates you; it is because to light a grip was used on the gun, particularly with your left hand!

Note: Without a consistence amount of grip with both hands the amount of muzzle lift will also change the trajectory (point of impact) down range each and every shot. Every shooter will hold the gun slightly different but ONLY when you become consistence in your GRIP, you can truly zero your slug gun. That’s why another person CANNOT truly zero someone else’s slug gun. Deer Rifles do the same thing but the projectiles are around 1/3 the weight, or less, of a slug, and the projectile spends less than 1/2 the time in the barrel. So the amount of the high left issue is greatly diminished.

Setting up your slug gun on the shooting bench:

You have just read all the technical reasons why the 20ga 2.2″ Schrifle 365gr Copper slug could move the muzzle around a lot before the slug exits the barrel; when firing off of a shooting bench. To begin with, start with how YOU physically set at the bench and how to set up your slug gun on the shooting bench. It is just as important as the technical side of controlling the slug gun itself. It would take a long time to explain how to do just that in writing. The TarHunt web site has a video that explains just that. All the major points are discussed in this video. It is well worth the 4.5 minutes it takes to view this video. BOLT ACTION ZEROING TECHNIQUES.

When you use the proper two handed grip and if you’re sitting in the right position behind the gun. UNLESS the slug gun slides straight back ON THE REST, with minimal muzzle lift, while the slug is in the barrel, you are going to continue to shoot large groups even at 50 yards.

Cause and effect/Shooter Just More Frendly: Is the 20ga the most accurate slug gun or just more shooter frendly?

That same unsealed jump is why the 2 ¾” (20ga or 12ga) round has less felt recoil when fired in a 3″ chamber. Everyone contends that the 2 ¾” 20ga round are more accurate than a 20ga 3” round. When the 2 ¾” round and the 3″ round, share the same weight slug; they are both loaded to the same pressure. Then WHY doses a Full Length 3″ Case always seems to kick more. Because the 3″ case sealed off a 3″ chamber right away, assuring Constance pressure and velocity, each and every round. The truth is the less felt recoil is due to the loss of chamber pressure by firing a 2 3/4″ round in a longer 3″ chamber. It just makes the 2 ¾” slug round MORE shooter friendly. The less the felt recoil the more consistent the shooter can shoot. When you buy the correct length plastic case, for your maximum chamber length, “full velocity, temperature and slug alignment” issues are mostly resolved.

Visit the [20ga NeoTec FLC 355gr Copper] slug pages, under the AMMO tab on the home page, for more 0n 2 3/4″ & 3″ slugs.

“NEVER fire a 3″ rounds in a 2 ¾” length chamber” Always remember; a 3″ case will fit into a 2 ¾” chamber and the action will close, it will even extract, as long as it is not fired! So be careful!

If a 3″ case is fired in a 2 ¾” chamber; pressures will GO WELL ABOVE EXCEPTABLE LIMINTS because the 3″ case does not have enough room to open fully. So the slug must literally TEAR off the end of the case before it can move down the barrel. That could be a disaster waiting to happen! SERIOUS INJURY MAY OCCUR TO THE SHOOTER, AND/OR BY STANDERS, and POSSIBLY DESTROY THE GUN! TarHunt assumes no responability for the misuse of any of the 20ga NeoTec FLC or Schrifle Copper slug rounds.

SHIPPING:

All orders will be shipped directly from TarHunt until further notice. Loaded ammunition or primed hulls; shipped by UPS ground service do not require a Haz-Mat fee. Any ammunition shipped by air service does require an Air Haz-Mat fee.

ATTENTION: Residents of CA, CT, DE, DC, IL, KS, MA, NY, WA, parts of OH, MD and most major population areas in any state. Check your local laws before ordering ammunition products over the internet. By placing an order with TarHunt web site or by phone; you certify that you are of legal age and satisfy all federal, state and local legal/regulatory requirements prior to purchase of ammunation and then have it shipped to your residents..

The NeoTec FLC line up: The other TarHunt bore size slug for 3″ chambered rifled barrels.

Availability: of the (16ga 2 3/4 NeoTec FLC) and the 2 ¾” or 3″ (12ga NeoTec™ FLC) rounds will depend on the PRICE AND AVAILABLITY OF THE .750 DIAMETER solid Copper rod they are precision machined from.

NOTE: Buy using this product the shooter assumes all responsibility for firing this round through any type of a fixed choke or choke tube, period! TarHunt is NOT responsible for any and all damages to the firearm(s), person(s) firing the firearm, and or person(s) as bystanders due to any misuse.

WARNING: FOR FULLY RIFLED BARRELS ONLY. Keep out of the reach of children!

“WARNING”

“NEVER fire a 3” rounds in a 2 ¾” length chamber” Always remember; it will fit into the chamber, the action will close, it will even extract as long as it is not fired! If it is fired in a 2 ¾” chamber; pressures will GO VERY HIGH because the 3″ case does not have enough room to fully OPEN. So the slug must literally TEAR off the end of the case before it can move down the barrel!